3D printing has become a new, futuristic tool for us to use on a daily basis. By just waiting a short period of time, a small figure of almost anything can go from a picture on a computer screen to a real-life 3D object.

Here at the University of North Florida, we also have our own 3D printing department sponsored by the Johnson & Johnson corporation. Split into a few areas on campus, there is a chain of 3D printers on the first floor of the President’s Office building and also in the Engineering Building, where it’s main chain of workers and development takes place.

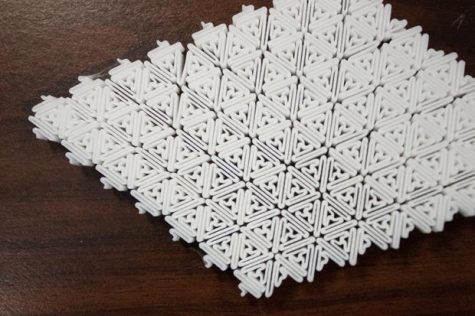

Worked on by the Center for Instruction & Research Technology (C.I.R.T), the group works diligently in their 3D printing area with the Marterbot Replicator 2.0, the model printer that is used for their creations. One of the workers in the department, Rey was able to shed some light on what they do in this workplace.

Using polymathic acid filament, or polymer side for short, Guo and his co-workers are able to create almost anything, whether it be medical tools for Johnson & Johnson group or things for the University.

Some jobs in the 3D printing field are Research and Development areas working with Johnson and Johnson, manufacturing, organizing, and also managing the medical tools and other 3D related products they make.

UNF’s Research and Development department within C.I.R.T. is doing its best to support the University with their needs and whenever 3D printing is involved. UNF faculty can use 3D resources for free and if it gets approved by the C.I.R.T. themselves, student projects can also be worked on as well.

Because of their work on campus and the ever-growing popularity, the 3D printing area is getting more money from the University to build a new 3D printing lab to further C.I.R.T.’s work.

__

For more information or news tips, or if you see an error in this story or have any compliments or concerns, contact editor@unfspinnaker.com.